MIL-DTL-44054C

4.1.1 Component and material inspection. Components and materials shall be inspected in

accordance with all the requirements of referenced documents unless otherwise excluded, amended,

modified, or qualified in this document or applicable purchase document. In addition, the bottles, caps,

and boxes shall be examined in accordance with 4.1.1.1 through 4.1.1.3. Bottles, with caps, shall be

tested for the characteristics specified in table II. The lot size shall be expressed in units of bottles with

caps. The sample unit shall be one bottle with cap. The inspection level shall be S-1 and the acceptable

quality limits (AQLs) expressed in terms of defects per hundred units, shall be 2.5.

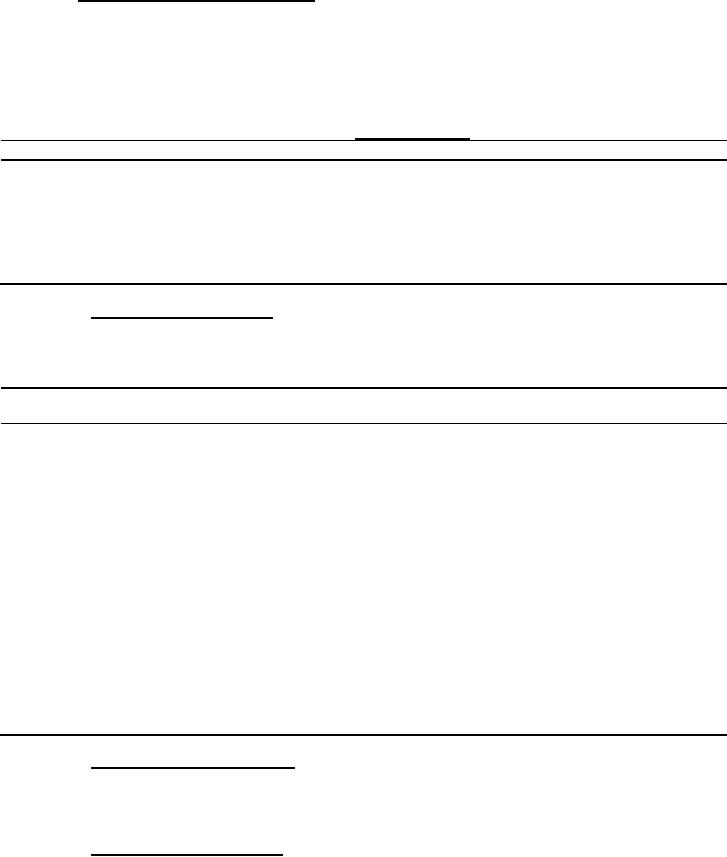

TABLE II - Component tests.

Characteristic

Requirement reference

Test method

Capacity

3.1.3

4.2.1

Leakage

3.1.3

4.2.2

Pen and pencil marking

3.1.4

4.2.3

capability

Legibility after marking

3.1.4

4.2.4

4.1.1.1 Bottle and cap examination. The bottles and caps shall be examined for the defects listed

below. The lot size shall be expressed in units of bottles with caps. The sample unit shall be one bottle

with cap. The inspection level shall be II and the AQL, expressed in terms of defects per hundred units,

shall be 2.5 for major defects and 4.0 for total (major and minor combined) defects.

Classification

Defect

Major

Minor

Bottle or cap not free of cracks, chips, or breaks

X

Bottle or cap not free of distortion

X

Bottle or cap not free of sharp edges or burrs

X

Top of bottle not flat or smooth

X

Bottle not clean, dry, or ready for use

X

Bottle not free of foreign matter

X

NOTE: Application of cap to bottle during capping may result in deposit

of some small plastic or fiber shavings in the bottle. Presence of a few

of these shavings shall not be considered a defect.

Liner not aligned or secured within screw cap

X

Bottle not stable when placed on a flat and level surface

X

Thread on cap or bottle not free of stripping, distortion or discontinuity

X

Cap not capable of being secured to bottle

X

Metal caps not free of corrosion

X

Bottle or cap not free of scratches, blemished or pits

X

Cap not clean

X

Bottle not free of imbedded foreign matter

X

Bottle not free of flash

X

4.1.1.2 Bottle dimensions examination. The bottle shall be examined for conformance to the

dimensions specified in table I. Any nonconformance to the specified dimensions shall be classified as a

defect. The lot size shall be expressed in units of bottles. The sample unit shall be one bottle. The

inspection level shall be S-3 and the AQL, expressed in terms of defects per hundred units, shall be 2.5.

4.1.1.3 Box (for bottles) examination. The boxes shall be examined for the defects listed below. The

lot size shall be expressed in units of boxes. The sample unit shall be one box. The inspection level shall

be II and the AQL, expressed in terms of defects per hundred units, shall be 2.5 for major defects and 4.0

for total (major and minor combined) defects.

5

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business